Main Office: +86-25-87151632

Email: wa@huadeasrs.com

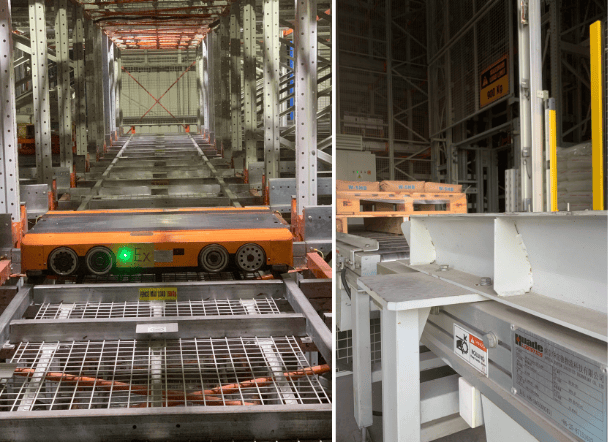

In the wave of logistics automation, the four-way shuttle system, with its modular design and multi-dimensional operational capabilities, has become a benchmark technology in the high-density storage field. As an innovator of traditional warehousing equipment, this system achieves breakthroughs in both space utilization and operational efficiency through its flexible horizontal and four-way shuttles, intelligent scheduling algorithms, and flexible racking.

Leading Technical Architecture

Four-dimensional motion control system

Utilizing dual-wheel independent drive technology, the four-way shuttle can steer freely on the X and Y axes, eliminating the need for external equipment to change lanes. A laser positioning and obstacle avoidance system ensures precise docking on complex paths, with an error control within ±2mm.

Modular expansion capabilities

The rack rails are manufactured using a fully automated rolling process using galvanized sheet metal, allowing for future expansion of the warehouse area or vertical height increases. New modules can be seamlessly integrated into the existing WMS system, avoiding duplication of investment.

Intelligent scheduling algorithm

Dynamically allocate tasks based on inventory distribution strategies, balance loads by pre-allocating return pallet addresses, and resolve path conflicts when multiple vehicles collaborate.

Irreplaceable commercial value

Space utilization is greatly improved

Compared with traditional stacker crane warehouses, it eliminates the need for fixed aisle design and increases storage density by 20%-100%, making it particularly suitable for urban warehousing scenarios with high land costs.

Flexible production adaptation

It supports dual-mode switching between first-in-first-out and first-in-last-out, meeting the stringent batch management requirements of industries such as food and medicine, while being compatible with irregular warehouse layouts.

Full-cycle cost advantage

The initial investment is 30% lower than that of a stacker crane system, energy consumption is reduced by 20%, and the number of shuttle vehicles can be increased or decreased to match the business demand during peak and off-seasons.

Deep adaptation to industry scenarios

For specialized applications like new energy and cold chain, the system features moisture- and collision-resistant storage locations to prevent damage caused by stacked storage. In the event of a surge in e-commerce orders, throughput can be linearly increased by increasing the number of shuttle vehicles.

Copyright @ 2026 Nanjing Huayide Logistics Technology Co., Ltd. All Rights Reserved.

network supported

network supported

Sitemap / Xml / Blog / Privacy Policy