Main Office: +86-25-87151632

Email: wa@huadeasrs.com

4 way pallet shuttles are a type of high-density automated storage solutions that use mobile satellite or “shuttles” to travel product pallets horizontally down rows of racking systems.

Automated four way pallet shuttle system

FAST

• Driving Speed, Direction Changing Speed

• Guarantee for System Efficiency

ACCURATE

• Running Accurately, Stop Accurately

• Cornerstone of stable operation

THIN

• Shorter and Thinner Vehicle Body

• Maximum Space Utilization

HOW DOES FOUR WAY PALLET SHUTTLE SYSTEM WORK?

A pallet shuttle system is an automated storage solution designed to improve the efficiency and accuracy of high-volume pallet storage and fulfillment. These systems use satellite vehicles to transport pallets to and from designated storage locations within a high-density, multi-level racking system, offering a efficient and safer alternative to traditional non-automated methods. A 4-way pallet shuttle system further elevates automated pallet storage by enabling movement in all four directions—forward, reverse, cross-aisle, and vertically. This multi-directional and cross directional capability allows seamless lane & aisle switching without additional equipment or manual intervention.

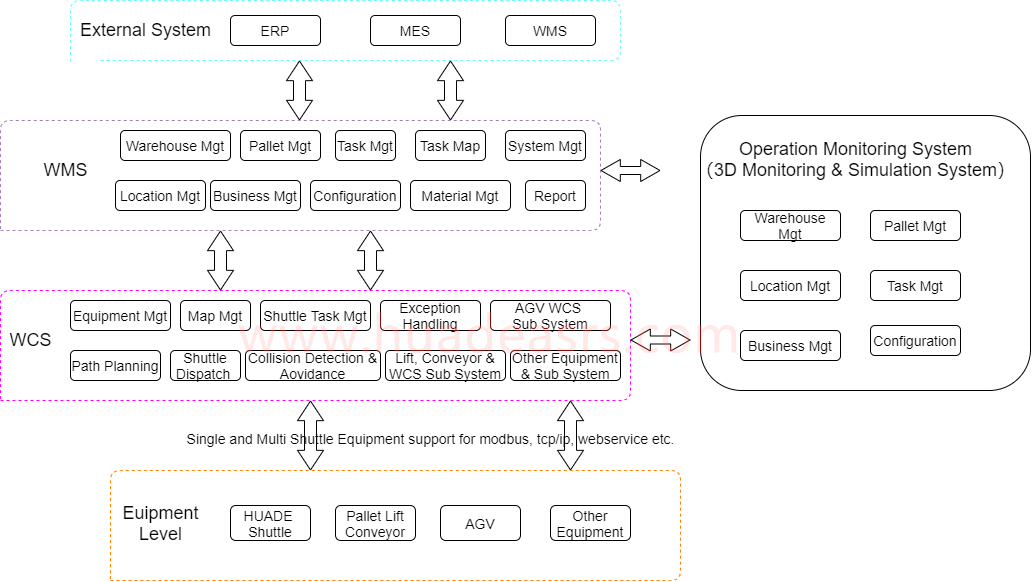

Excelling in dynamic, high-density environments, the Four-way shuttle warehouse offers enhanced flexibility, superior space optimization, and increased throughput compared to 2-way systems. Integrated with Warehouse Management System (WMS) and Warehouse Control System (WCS) software, the system ensures precise coordination, efficient inventory management, and seamless operation across all levels of the storage process.

Further automation is achieved with integrated pallet lifter that transport pallet loads to designated levels within the system for storage. These Lifters also retrieve pallets from storage and deliver them to pallet conveyors for takeaway, significantly reducing reliance on forklifts and manual operations while streamlining overall workflow. The more levels, the more cost-effective your system becomes.

HUADE FOUR WAY PALLET SHUTTLE PROFILES

| ITEM | Shuttle Body (L*W*H ) | Pallet Dimension |

| Standard Shuttle Dimension | 1100L*980W*150Hmm | 1200W*1000D |

| 1200L*980W*150Hmm | 1200W*1100D | |

| 1300L*980W*150Hmm | 1200W*1200D | |

| Self Weight | 450kg | |

| Loading Capacity | 1000kg | |

| Lifting Distance | 40mm, ≤5s | |

| Working Temperature | 0-40℃ | |

| Communication Mode | Wireless AP | |

| Power Supply | lithium battery, 48V36 /45 /60AH | ≥8H continuous work |

| Driving Speed (empty) | 1.5m/s | |

| Driving Speed (load) | 1.0m/s | |

| Acceleration | 0.3m/S2 | |

| Battery Service Life | 2000 charging times | 1.5-2H charging time |

| Addressing | Laser, ±2mm |

HUADE latest four way shuttle transport technology (rack entry vehicle) enables these multiple deep pallets at any level can be accessed. The solution can be applied into a smaller building footprint, and in return less impact on its surrounding environment.

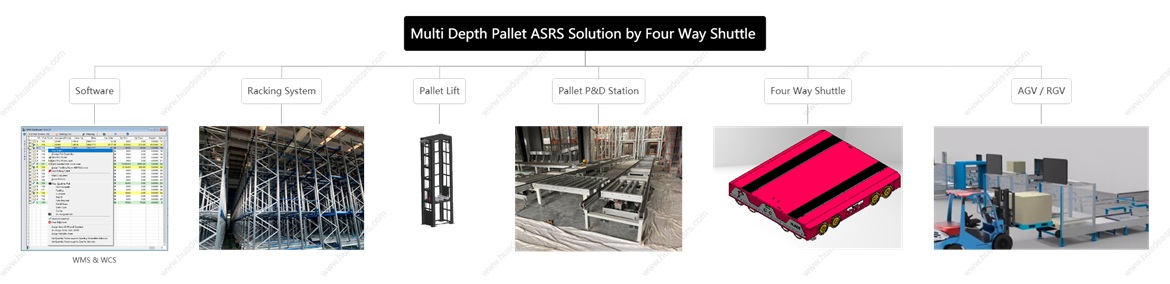

Typical Four Way Pallet Shuttle Components:

All system components of Four Way Shuttle ASRS are designed, engineered and manufactured by ourselves to ensure system compatibility and long useful life. Our hardware over time has resulted in enhanced safety and design plus advanced technology and functionality, providing you with a unique, automated, high density storage solution.

HUAYIDE believes that in the ASRS solution, "software defines hardware", and software determines the fluency and cooperation of hardware. Hence four way pallet shuttle system is built on our own WMS & WCS, which realizes the dynamic management of stored items in the warehouse to ensure that the physical inventory is consistent with the account. Along with real-time data transmission with ERP, WMS assesses orders, inventory, labor and material handling systems to effectively execute order fulfillment. From storage to picking and all the way through shipping, WMS determines the most productive flow and resource allocation. We also provide accurate zone visibility of downstream capacities, destination availability & each equipment status to most effectively utilize your warehouse storage space.

Applications of Four Way Pallet Shuttle ASRS:

Feature: High-density & Flexible Aisle

Feature: WMS flexible location assignment

Feature: Multiple Shuttles

Feature: Flexible Aisle Design

WMS flexible location assignment

Multiple Shuttles

How to select proper pallet storage system?

There are a wide variety of shuttle styles and models. This is where understanding order profiles, inventory quantity, space restraints, labor sensitivity, business case, down-time, budget and much more need to be scrutinized to determine the best (most efficient and cost-effective) solution. Shuttle Based AS/RS can be used in a wide variety of applications which bringing you many operational, security and productivity benefits. Contact us today to evaluate the most appropriate pallet shuttle solutions that works for your manufacturing or distribution operation.

Copyright @ 2026 Nanjing Huayide Logistics Technology Co., Ltd. All Rights Reserved.

network supported

network supported

Sitemap / Xml / Blog / Privacy Policy