Fully automated warehouse systems are ideal solution for the frozen warehouse. Energy efficiency and a high degree of automation are economical, scalable, tailor-made and precisely maintain the quality of perishable goods in temperature controlled warehouse.

1.Rack System

Type Selection: Modular rack structures with strong load-bearing capacity (e.g., pallet racks for full pallets, shuttle racks for high-frequency operations).

Material: Low-temperature-resistant, anti-corrosion steel ensures durability in humid, freezing environments.

2.Stacker Crane System

![]()

Type: Single-column for lighter goods, double-column for heavy loads and high-bay racks.

![]()

Control: PLC-based automation with laser or encoder positioning for precise pallet handling.

3. Conveyor System

Type: Belt, roller, or chain conveyors designed for low-temperature performance.

Layout Planning: Streamlined U-shaped or S-shaped flow ensuring efficient goods movement between zones.

4. Warehouse Management System (WMS)

![]() Inventory Management: Real-time inbound/outbound tracking, stock alerts, and automated adjustments.

Inventory Management: Real-time inbound/outbound tracking, stock alerts, and automated adjustments.

![]()

Equipment Scheduling: Intelligent coordination of stacker cranes, shuttles, and conveyors for optimized workflow.

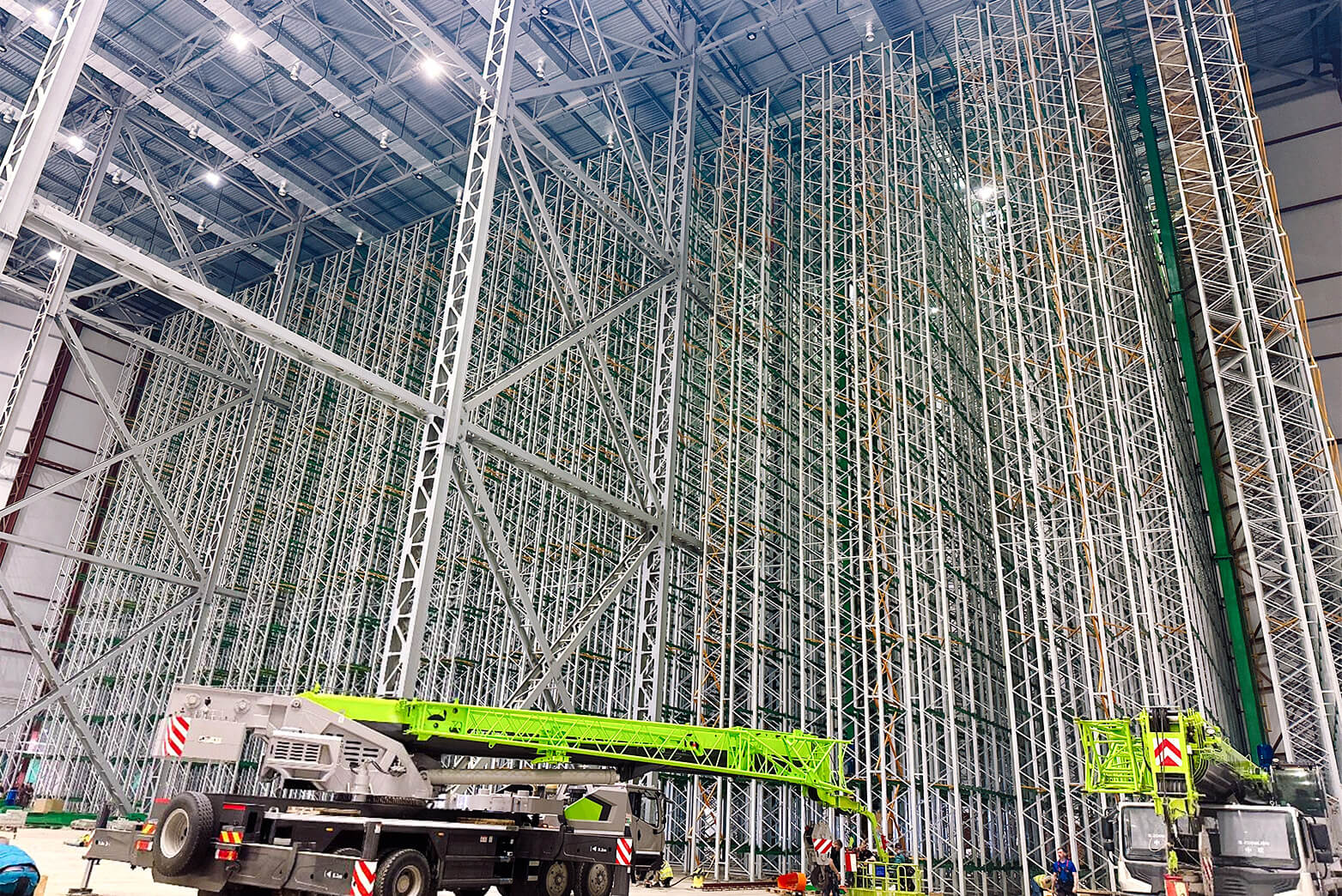

Huade implemented a 36m-high automated warehouse for a beverage manufacturer in Russia, integrating AS/RS, pallet shuttle systems, and WMS for full batch traceability.

![]() +40% storage density increase

+40% storage density increase

![]() -35% order processing time

-35% order processing time

![]() 100% FIFO/FEFO Control accuracy

100% FIFO/FEFO Control accuracy

Copyright @ 2026 Nanjing Huayide Logistics Technology Co., Ltd. All Rights Reserved.

network supported

network supported

Sitemap / Xml / Blog / Privacy Policy