Huade offers customised warehouse automation systems for the beverage sector: from high-density AS/RS and 4-way pallet shuttles to RGV loops, conveyors and automatic case picking. Our data-driven design ensures cost-effective solutions with short payback periods.

Beverage manufacturers face unique logistics hurdles: managing mixed SKUs in varying volumes, coping with seasonal demand peaks, and maintaining hygiene-compliant storage facilities. With frequent product innovation and shifting consumer behaviour, flexibility and speed are more critical than ever.

There's no one-size-fit-all package solution fit for all beverage automated warehouse. We know the challeges facing today's beverage industry, the automated solutions we provide based on our pallet ASRS, 4D pallet shuttles, RGV loop, pallet conveyor and automatic case picking. Provide a data-driven, cost-effective solution with a short amortization period is at heart of everything we do.Our automated warehouse supports beverage manufacturers to stay as flexible as possible, to maximize storage capacity, improve efficiency, enhance productivity and deliver fresh beverages to customers fast. You have the agility to react to promotions, seasonal and long-term changes in customer demand.

Flexible High-Density AS/RS

Flexible High-Density AS/RS

Pallet Shuttle & Conveyors

Pallet Shuttle & Conveyors

WMS & WCS Integration

WMS & WCS Integration

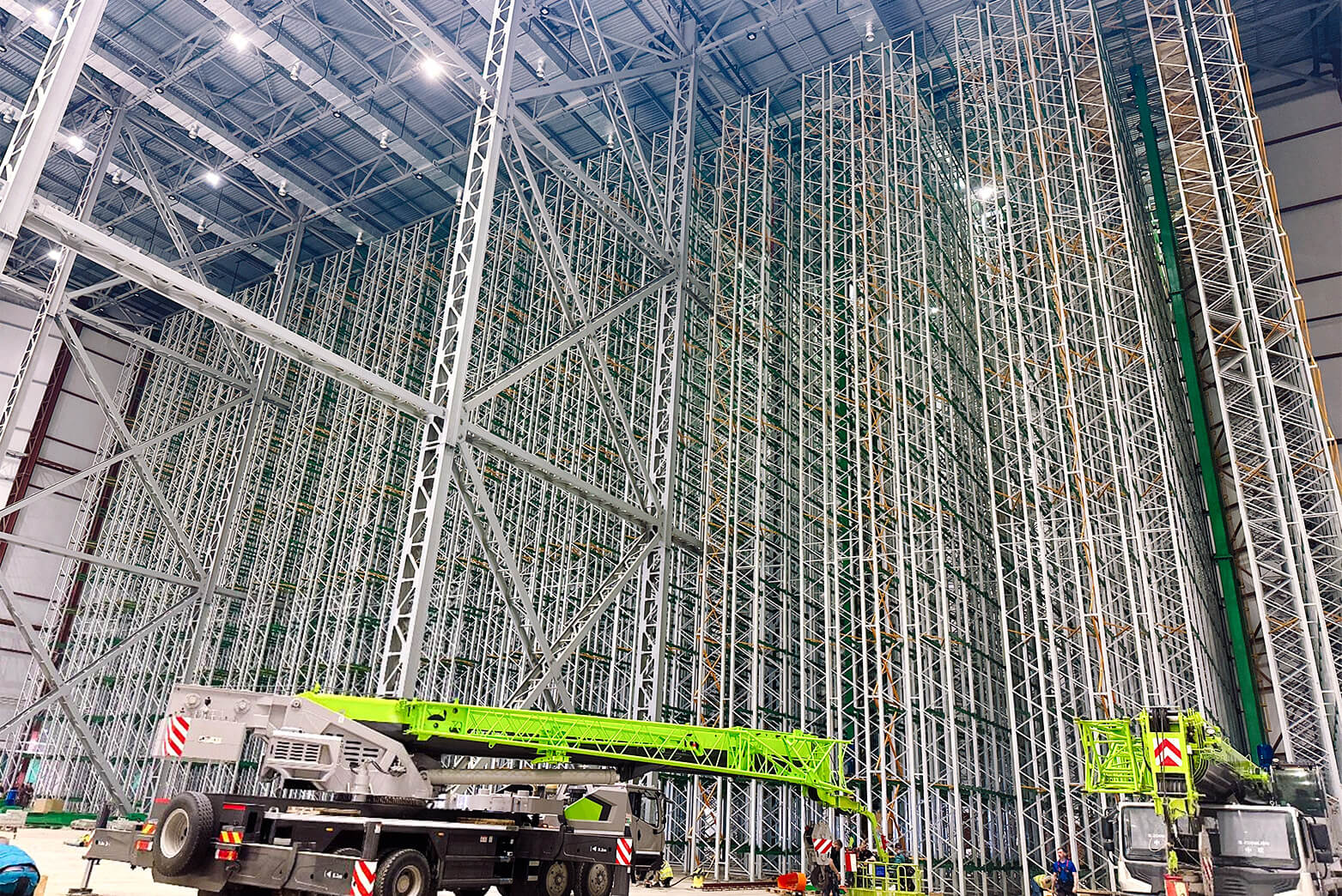

Huade implemented a 36m-high automated warehouse for a beverage manufacturer in Russia, integrating AS/RS, pallet shuttle systems, and WMS for full batch traceability.

![]() +40% storage density increase

+40% storage density increase

![]() -35% order processing time

-35% order processing time

![]() 100% FIFO/FEFO Control accuracy

100% FIFO/FEFO Control accuracy

Copyright @ 2026 Nanjing Huayide Logistics Technology Co., Ltd. All Rights Reserved.

network supported

network supported

Sitemap / Xml / Blog / Privacy Policy