Huade Logistics offers advanced automated warehousing services specifically designed to meet the diverse challenges of the chemical industry.

Regulatory Compliance: Strict adherence to OSHA, EPA, and international chemical safety standards (REACH, GHS) is mandatory for legal operation and liability protection.

![]() High labor costs due to specialized handling requirements

High labor costs due to specialized handling requirements

![]() Inefficient space utilization with manual storage systems

Inefficient space utilization with manual storage systems

![]() Inventory inaccuracies leading to stockouts or overstock

Inventory inaccuracies leading to stockouts or overstock

![]() Extended order processing times affecting customer satisfaction

Extended order processing times affecting customer satisfaction

![]() High energy consumption from specialized storage conditions

High energy consumption from specialized storage conditions

Custom-engineered systems designed to address the unique challenges of chemical storage and distribution

Our customized storage solutions maximize space while ensuring strict chemical safety. We design specialized shelves and containers based on the chemical form (liquid, solid, gas) and properties (corrosive, flammable, etc.). For example, liquid chemicals are stored in corrosion-resistant, leak-proof tanks, while solid chemicals use sealed, fire-resistant shelving. By leveraging high-bay racks and automated stackers, storage density is significantly increased compared to traditional warehouses.

![]() High-density racking systems with specialized containment

High-density racking systems with specialized containment

![]() Temperature and humidity-controlled zones

Temperature and humidity-controlled zones

![]() Customized storage for hazardous and non-hazardous materials

Customized storage for hazardous and non-hazardous materials

![]() Vertical storage solutions to maximize floor space

Vertical storage solutions to maximize floor space

![]() Automated retrieval systems for high-bay storage

Automated retrieval systems for high-bay storage

Our integrated safety systems enable real-time monitoring and fast emergency response in chemical warehouses. High-precision sensors track temperature, humidity, pressure, and potential leaks, triggering alarms and actions such as ventilation or power shutdown when abnormalities appear. Advanced fire and explosion-proof measures—automatic sprinklers, gas extinguishers, explosion-proof barriers, and isolation facilities—work in coordination with automated controls for rapid, linked safety response.

Safety Compliance: Our systems meet or exceed NFPA, OSHA, and international safety standards for chemical storage facilities.

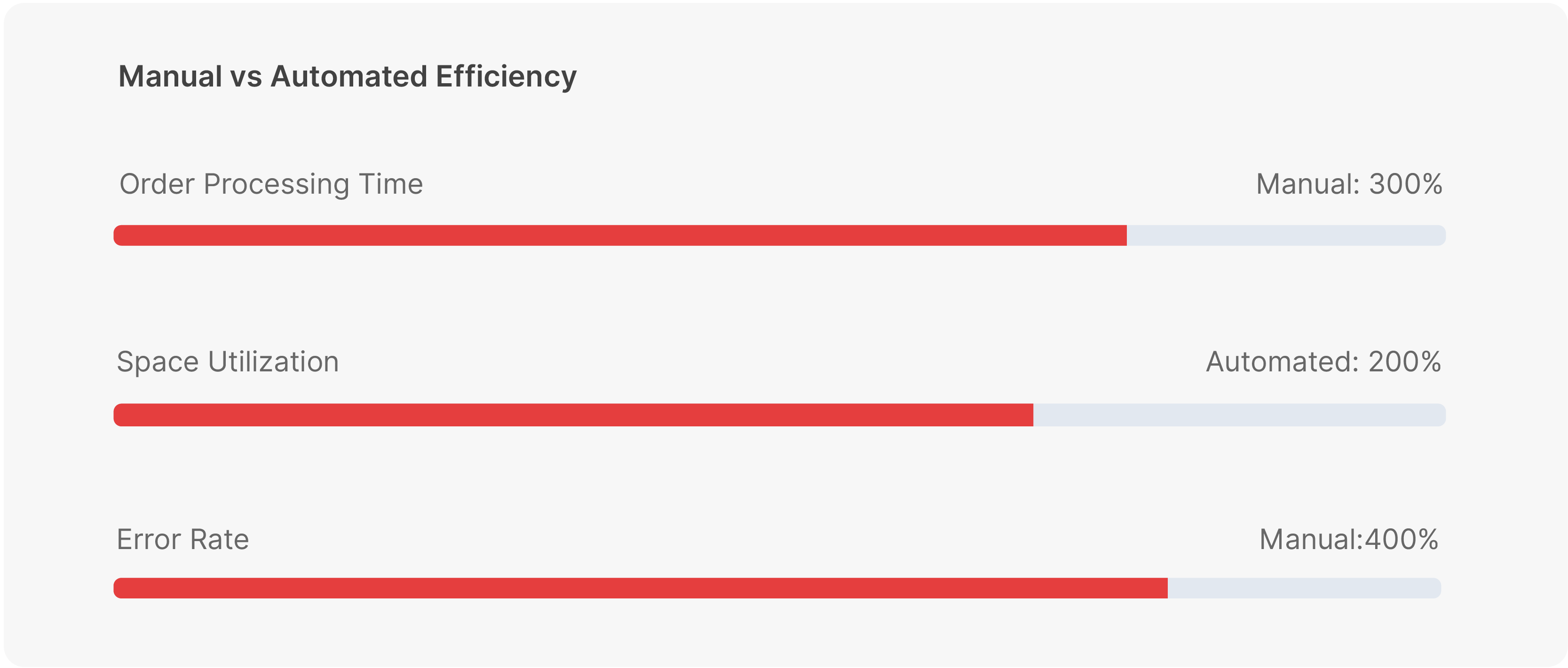

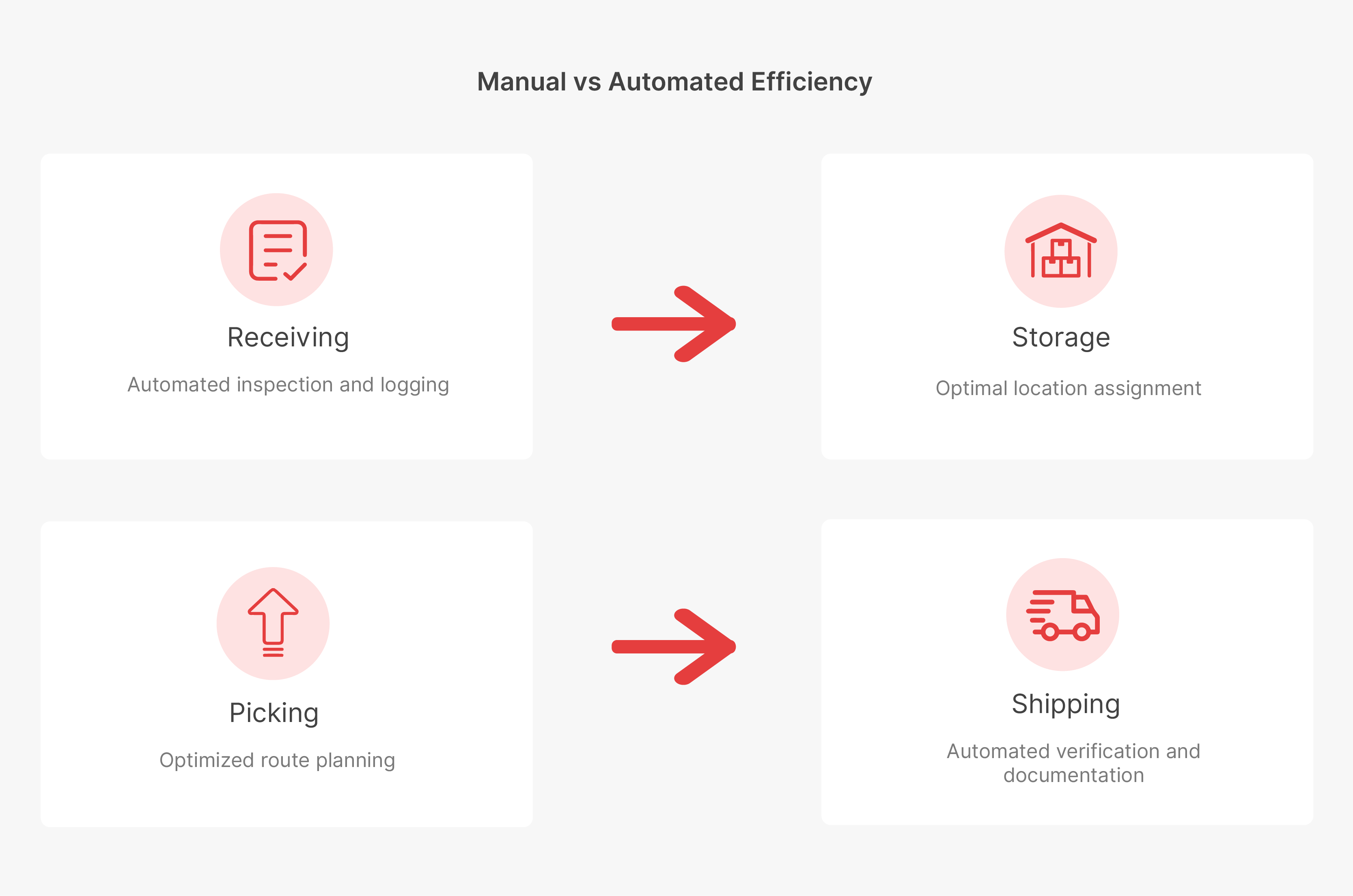

Our integrated automation solutions reduce manual labor and greatly boost throughput and accuracy. Automated handling equipment such as AGVs and stackers replace manual loading and transport, completing tasks quickly and precisely. A warehouse management system (WMS) tracks product movements, inventory levels, and shelf life in real time, enabling better purchasing and sales planning while reducing backlogs and stockouts.

Our sustainable solutions minimize environmental impact and reduce long-term operating costs. Leakage prevention pallets, collection pools, and recovery systems prevent chemical spread and enable safe treatment of spills. Energy management measures—optimized lighting, temperature control, and ventilation with high-efficiency and smart equipment—help lower overall energy consumption.

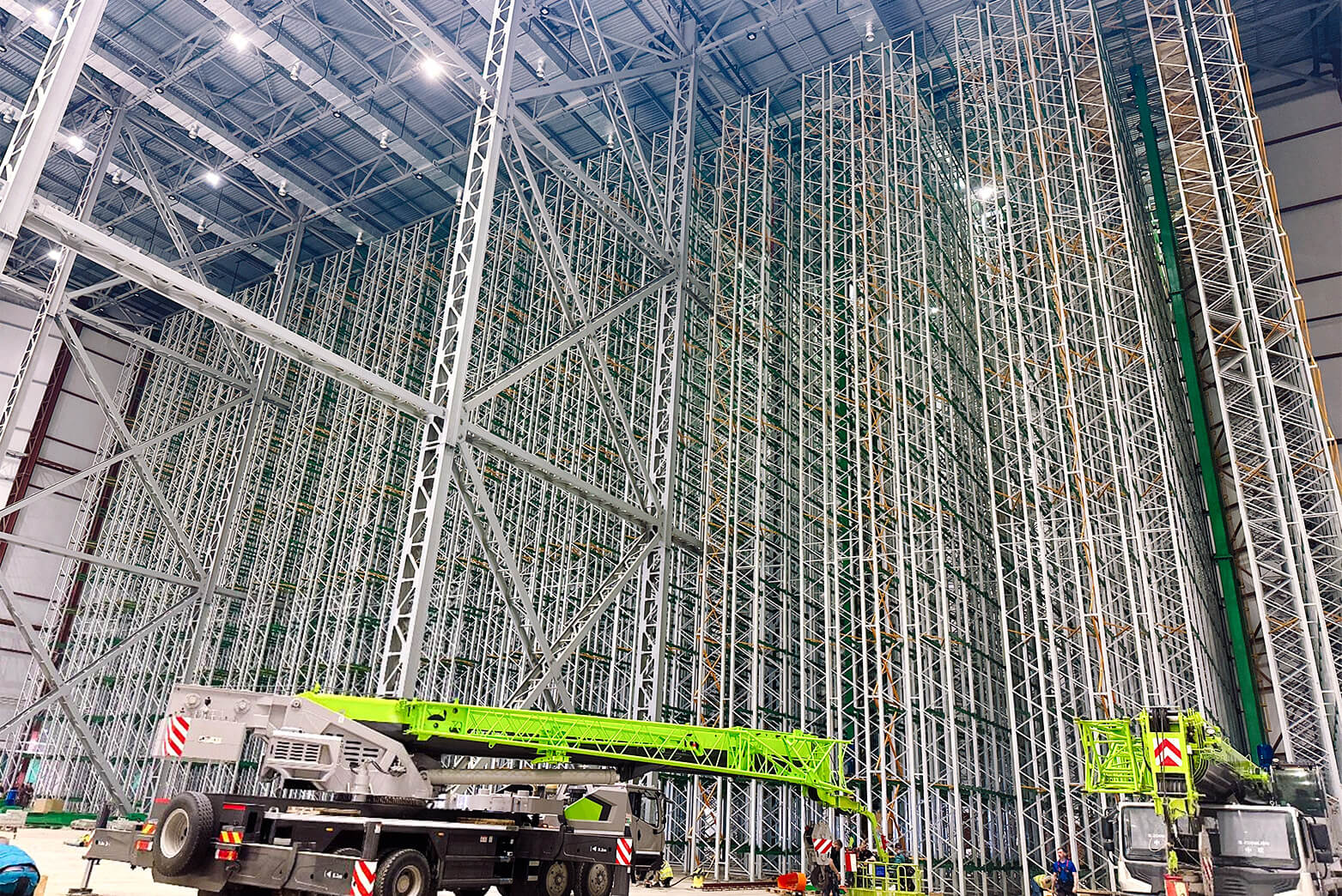

Huade implemented a 36m-high automated warehouse for a beverage manufacturer in Russia, integrating AS/RS, pallet shuttle systems, and WMS for full batch traceability.

![]() +40% storage density increase

+40% storage density increase

![]() -35% order processing time

-35% order processing time

![]() 100% FIFO/FEFO Control accuracy

100% FIFO/FEFO Control accuracy

Copyright @ 2026 Nanjing Huayide Logistics Technology Co., Ltd. All Rights Reserved.

network supported

network supported

Sitemap / Xml / Blog / Privacy Policy