Huade Logistics offers customized Automated Storage & Retrieval Systems (AS/RS), Pallet Shuttle Systems, and Intelligent WMS/WCS designed specifically for the food manufacturing and cold chain sector. Our integrated solutions ensure FIFO/FEFO control, batch tracking, and hygienic material handling from inbound to outbound.

INDUSTRY CHALLENGE

INDUSTRY CHALLENGE

Food manufacturers face increasing logistics challenges: ensuring food safety, maintaining temperature control, and complying with strict hygiene standards. Frequent SKU changes, mixed packaging formats, and short shelf life require fast, accurate, and traceable warehouse operations that traditional manual handling cannot deliver efficiently.

Huade's Automated Solutions For The Food Industry

Huade Solutions opens visibility to your operation so you can manage proactively when and where you need it. Some technologies and solutions that help support the food industry include: Data-driven consultation,Goods-to-person systems, ASRS, Mini load or shuttle based automated for case handling, Crane-based automation for pallet handling, Plastic belt conveyor for food processing, Robotic packaging, Mixed case palletizing.

High-Density AS/RS

High-Density AS/RS

Pallet Shuttle & Conveying Systems

Pallet Shuttle & Conveying Systems

WMS & WCS Integration

WMS & WCS Integration

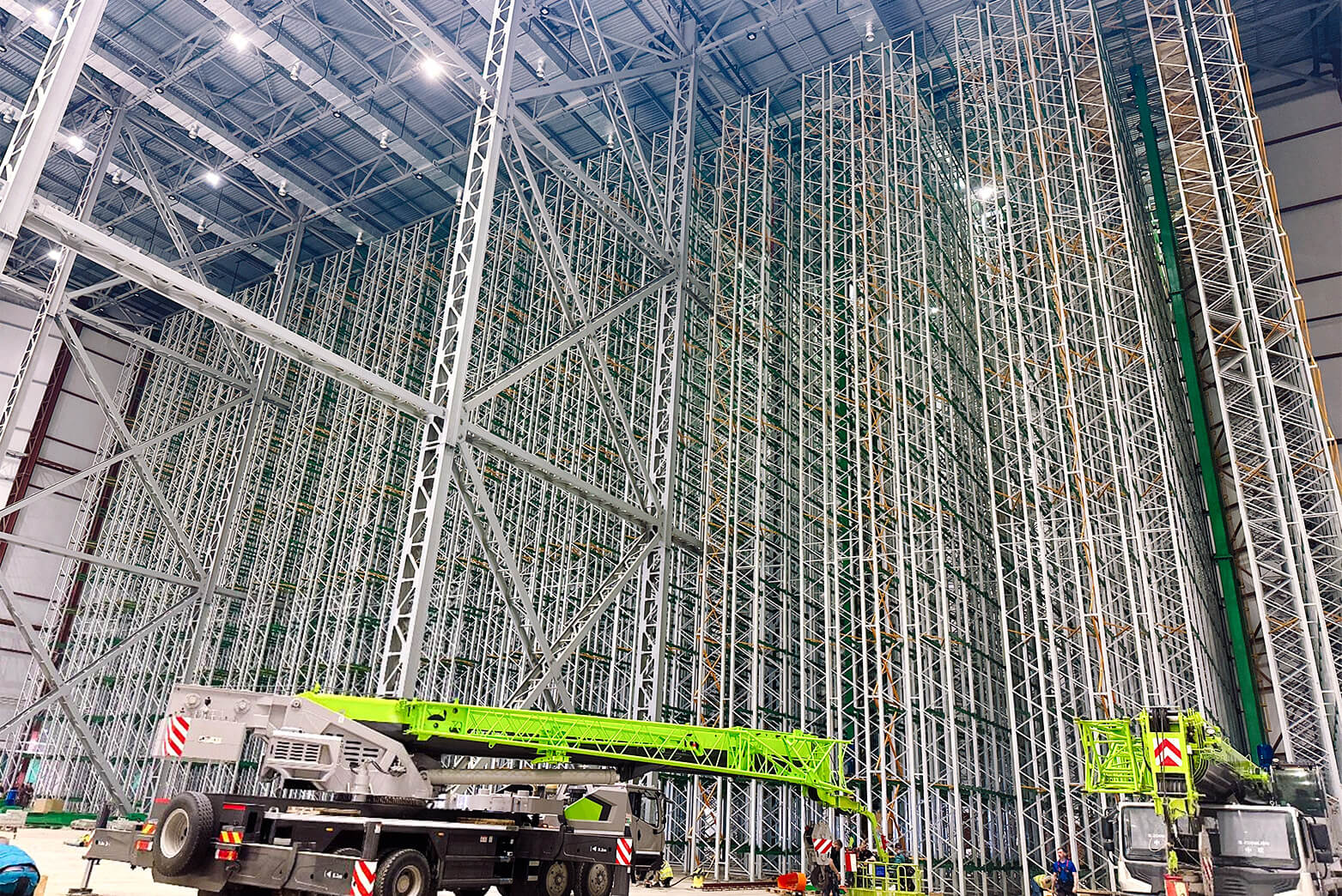

Huade implemented a 36m-high automated warehouse for a beverage manufacturer in Russia, integrating AS/RS, pallet shuttle systems, and WMS for full batch traceability.

![]() +40% storage density increase

+40% storage density increase

![]() -35% order processing time

-35% order processing time

![]() 100% FIFO/FEFO Control accuracy

100% FIFO/FEFO Control accuracy

Copyright @ 2026 Nanjing Huayide Logistics Technology Co., Ltd. All Rights Reserved.

network supported

network supported

Sitemap / Xml / Blog / Privacy Policy