Radio Shuttle Pallet Rack System is a semi-automated system conjunction with forklift trucks for storage of goods with low variety but high volumes per SKU. This system is highly recommended in manufacturing businesses, especially those fast moving consumer goods, food, beverage and cold chain industries.

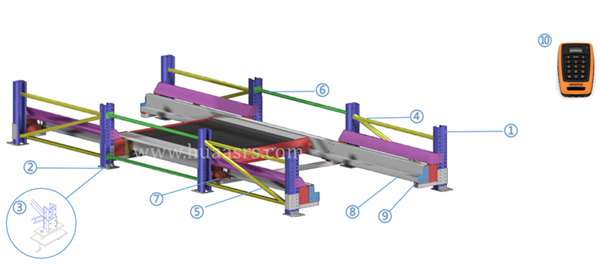

System Components:

How does it works?

The shuttle rack system consists of two major components: High Density Open Face Pallet Racking System and Battery-powered radio shuttles. Forklift places a shuttle at the end of lane before selecting an operation mode by using the remote controller. The lanes are fed pallets by the programmable mobile shuttles. The number of shuttles can be adjusted to match throughput demand. Shuttle retrieves, deposits, and reshuffles the pallet in the racking storing lanes and moved by means of traditional forklift.This system solution is also available for cold storage with temperatures of up to -30°C.

High Density Pallet Racking System

An important group of storage solutions used for warehouse fulfillment tasks, apart from those allowing direct access to each pallet. This high-density rack group includes solutions with Drive-In/Drive-Thru Rack, Gravity Flow Rack, Shuttle Storage Rack System, Mobile Racking.

Although each of these rack systems naturally has its own unique features, they do share a number of common characteristics.

The fact that they are compact systems means they make better use of space. However, they are best used though when there are a large number of pallets with the same SKU, which means one channel should contain only one SKU.

Raido Shuttle (HUADE Pallet Shuttle)

The radio shuttle (also known as pallet shuttle) system is based on both FIFO and LIFO inventory management principles. It is equipped with rechargeable iron ion battery, if the racks are open on one end, the storing and picking of the pallets is done from the same end which means that the first pallet to go in will be the last one to come out (LIFO). If the racks are open from opposite ends, then the storing and picking will be done on opposite ends without any interference. This means that the first pallet to go in will be the first one to come out (FIFO).

Copyright @ 2025 Nanjing Huayide Logistics Technology Co., Ltd. All Rights Reserved.

network supported

network supported

Sitemap / Xml / Blog / Privacy Policy