Warehouse automation is not just about reducing labor costs. It is about achieving higher throughput, consistent accuracy, and long-term operational reliability. Automated systems such as stacker crane for pallets loads storage and handling, warehouse vertical lifts for automation, and automated pallet transfer systems are now considered essential infrastructure in modern distribution centers. However, just like any mechanical system, the lifespan of these solutions depends heavily on design, usage, and maintenance.

The operational life of automated equipment is rarely a fixed number. Instead, it is influenced by several variables:

| Factor | Typical Impact on Lifespan | Notes |

| Load capacity utilization | High loads shorten lifespan | Over 80% capacity reduces motor life by ~25% |

| Operating environment | Dust, humidity, or temperature swings accelerate wear | Ideal: 18–25°C, low dust |

| Maintenance frequency | Preventive maintenance extends life up to 40% | Lack of lubrication is a top failure cause |

| System design and quality | Higher-grade components last longer | ISO-certified designs often run 20% longer |

| Operator training | Improper use reduces service hours | Error-induced stoppages shorten gearbox life |

For example, data from the European Materials Handling Federation shows that Stacker crane for pallets loads storage and Handling in clean and well-maintained environments can operate efficiently for 15–20 years, whereas neglected systems may require major replacements within 8–10 years.

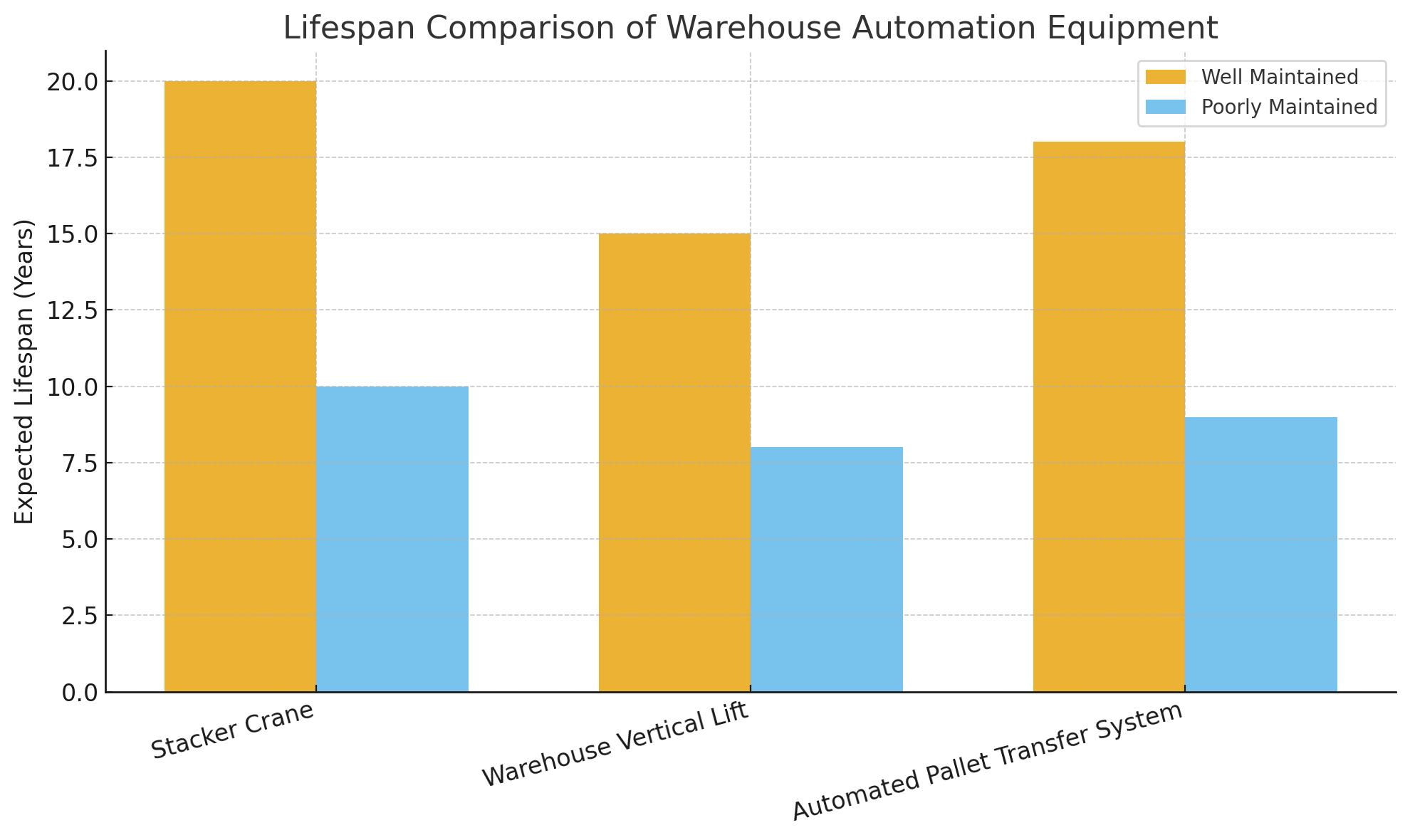

The chart above compares the expected operational lifespan of three core warehouse automation systems—Stacker crane for pallets loads storage and Handling, Warehouse Vertical Lifts For Automation, and the Automated Pallet Transfer System—under different maintenance conditions.

This data highlights why routine servicing, condition monitoring, and timely parts replacement are not just best practices but critical investments in warehouse efficiency.

Automated systems rarely fail without signals. Recognizing early indicators is critical to avoiding unplanned downtime.

A warehouse vertical lift system that starts consuming 10–15% more electricity than average may have worn motors or misaligned rails.

If an automated pallet transfer system starts misplacing pallets once in every 500 cycles instead of 1 in 5,000, it is a red flag.

Bearings and gearboxes in stacker cranes often emit noticeable vibration before major failure.

When a unit load stacker crane begins to take 12 seconds for a retrieval cycle instead of the designed 8–9 seconds, performance degradation is evident.

Industry benchmarks suggest that more than 4% downtime per month is considered excessive in automated warehouses.

Extending the operational lifespan of warehouse automation requires a mix of technical upgrades and disciplined maintenance.

Lubricate critical components at intervals recommended by the manufacturer.

Employ vibration sensors and thermal cameras to predict failures before they occur.

Avoid running cranes or lifts at maximum rated load continuously. Operating at 70–80% of maximum load increases system life by nearly 30%.

Dust filters, temperature regulation, and humidity control prevent premature wear on sensitive electronics and motors.

Retrofitting older systems with modern PLCs (programmable logic controllers) or servo drives can improve precision and reduce stress on mechanical parts.

A well-trained operator can reduce collision-related incidents by more than 40%, according to field studies in high-bay warehouses.

Automating a warehouse is a long-term investment. Choosing equipment like stacker crane for pallets loads storage and handling or warehouse vertical lifts for automation without considering lifecycle costs can result in premature replacements. A holistic approach involves:

Evaluating total cost of ownership (TCO) instead of upfront cost.

Planning maintenance budgets from the start.

Creating a replacement roadmap for components with shorter service lives (e.g., sensors, rollers).

When properly implemented, an automated pallet transfer system can run reliably for more than 15 years, provided it is supported by predictive analytics and scheduled inspections.

| Equipment Type | Expected Lifespan (well maintained) | Reduced Lifespan (poorly maintained) |

| Stacker Crane for Pallets Loads Storage | 18–20 years | 8–10 years |

| Warehouse Vertical Lifts for Automation | 12–15 years | 6–8 years |

| Automated Pallet Transfer System | 15–18 years | 7–9 years |

Warehouse automation is no longer optional for businesses aiming to scale. But automation alone does not guarantee efficiency. The lifespan of systems is directly tied to how they are managed—from load control to predictive maintenance. By observing early warning signs and investing in regular upkeep, companies can maximize the return on their automation investments and ensure systems deliver reliable performance for decades.

Copyright @ 2026 Nanjing Huayide Logistics Technology Co., Ltd. All Rights Reserved.

network supported

network supported

Sitemap / Xml / Blog / Privacy Policy