Main Office: +86-25-87151632

Email: wa@huadeasrs.com

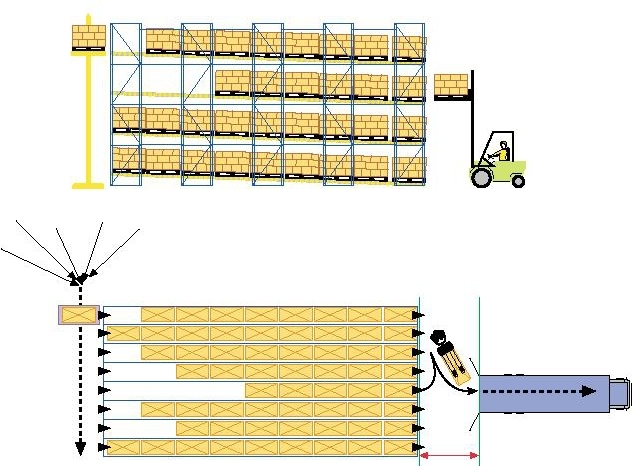

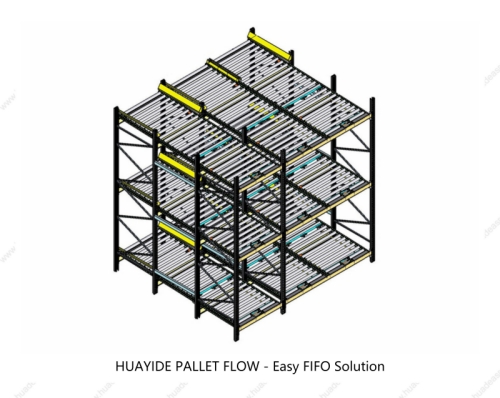

Pallet flow racks ideal for dynamic pallet storage high turnover perishable goods and high consumption products. Saves time in pallet handling. Maximum capacity.

Live Racking

Live Racking- also known as ‘Pallet Live Storage’ or 'Pallet Flow Rack' enables you to perfectly operate the stored products rotation with the FIFO (First-in, First-out) system in the critical stock turnover control but space constraints warehouses. Stored goods with an expiry date or product batches are easier to be monitored.

This Pallet live storage racking systems are used as buffer storage for shipping, in production and also for incoming and outgoing goods. The racks are usually accessed using front forklifts and reach trucks. Manual lifting trolleys can also be used for the lowest level at the removal side. Dynamic flow racks work via gravity flow alone and do not require any electrical source. The design of the gravity roller conveyors can be adapted to the specific goods using different roll divisions and brake rollers.

The other advantages of this high-density dynamic flow storage system are the optimum use of space as well as the ability to integrate automated warehouse with live racking. Furthermore, the pallets can also be accessed on multiple stories with additional order picking levels or tunnels.

Live System Design options for Different Warehouse

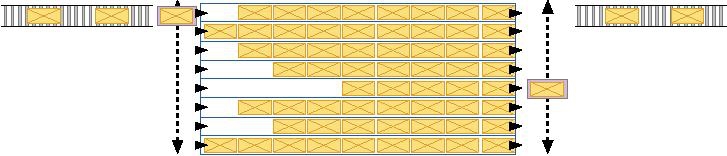

SHIPPING AREA

Rapid truck loading, each gravity racking channel fulfill a complete truck loading capacity

BUFFER STORAGE

Live pallet racking system is an ideal solution for short-term pallet buffer storage

Compact structure and multi-layer space saving pallet flow

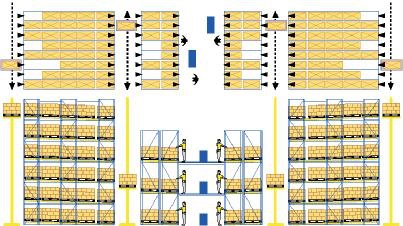

LIVING RACK FOR PICKING OPERATION

No potential clashes between equipment for loading pallets and personnel preparing orders. Picker safety operation is ensured

Picking operation can be done from both sides of aisle simultaneously

Stacker crane will replenish pallet to distribution channel automatically

LIVE STORAGE WITH MULTI LEVEL OPERATION

Storage and distribution can be done in multi level floor and channels

Combination of personnel picking and automatically pallet replenishment always the most efficient solution

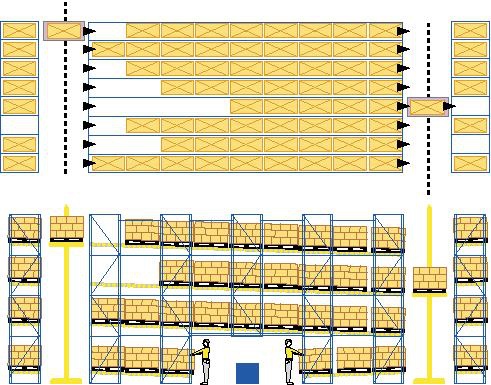

FIFO Flow Storage Components

The live storage warehouse consists of gravity roller conveyors installed in a advantage mechanical rack as live storage levels. Our Pallet Flow system offers a dynamic system solution with integrated conveyor modules to suit different pallet types and sizes.

Pallets travel smoothly on full-width or twin-track roller runway. While the front pallet is removed on the front side of the rack, the rear pallet is held. Thanks to automatic braking roller and pallet retainer, along with a combined load guide and end stop unit, pallet movement is always safe and smooth With this system you can use up to 60% less space than if you were to use conventional pallet racking.

Automated Warehouse with Live Racking

Live rack can be integrated to fully-automated warehouse operation.

WMS issues orders to WCS, the related equipment will carry out these orders without human intervention.

Goods can be taken out by using stacker crane or reach truck, which receive their orders via radio frequency.

In many cases we provided, a single stacker crane is installed on one side of racking, to place pallet into storage. On the other side, retrieval of the pallets is performed by counter balance forklift, in turn load the vehicle from dispatch.

Advantages

Applications

China Live Pallet Rack Storage System- In house testing, we supply we guarantee

We provide in-house testing facility to ensure the proper system design to fit your pallet, product, and workflow. Rail types, rail pitch, roller quantity and brake roller spacing are customized, then go through very thorough and system testing to ensure the positive rates of flow for the long haul. A videotape of these tests is provided for your approval and 100% satisfaction before each shipment.

Copyright @ 2026 Nanjing Huayide Logistics Technology Co., Ltd. All Rights Reserved.

network supported

network supported

Sitemap / Xml / Blog / Privacy Policy