Choosing the right warehouse racking system is essential for maximizing space efficiency, improving accessibility, and ensuring smooth material handling. Different designs are available to meet specific needs, ranging from high-density storage to specialized solutions for irregular goods. Understanding the options helps warehouse managers make informed decisions.

High-Density Storage Options

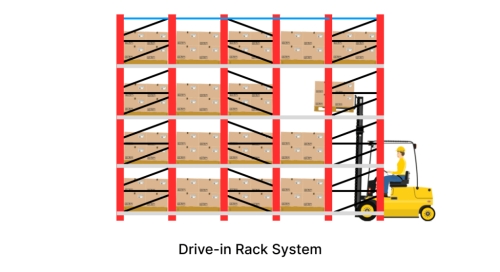

For facilities that need to store large volumes of similar items, high-density solutions are often preferred. One example is the Drive In Racking System, which reduces the number of aisles and allows forklifts to move directly into the rack structure. This design can increase space utilization by up to 80% compared with standard racking. It is widely used in cold storage, food, and beverage industries where inventory rotation is less critical.

Another variation is the Push Back Racking System, which uses nested carts on inclined rails to allow pallets to be stored several deep. Unlike drive-in racks, this system provides better selectivity, as pallets can be retrieved without entering the rack.

Storage for Long or Bulky Items

Not all products fit neatly onto pallets. For irregular or oversized goods such as pipes, timber, and sheet panels, the Cantilever Racking Storage System is particularly effective. With arms extending outward from a central column and no front vertical obstruction, it allows easy loading and unloading of long materials. This system is common in building material warehouses and steel distribution centers.

In addition, Mezzanine Racking Systems are sometimes used to create extra storage levels for bulky items or products that require manual handling. This design helps maximize vertical space without expanding the warehouse footprint.

Systems Supporting Inventory Rotation

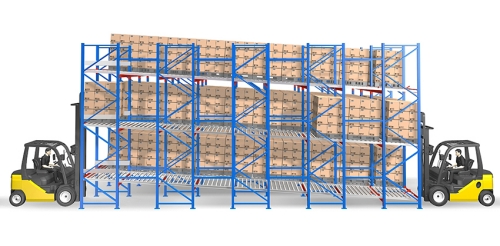

When stock rotation is essential, gravity-based systems are the most effective. The Pallet Flow Racking System uses roller tracks to automatically move pallets from the loading side to the picking side. Operating on a first-in, first-out principle, it ensures older stock is retrieved first, which is crucial for perishable goods and pharmaceuticals. Industry data shows that pallet flow racks can improve picking efficiency by 20–30% compared with conventional systems.

Another option is Selective Pallet Racking, the most widely used system worldwide. It provides direct access to every pallet, making it ideal for warehouses with diverse product ranges and high turnover rates. Although space utilization is lower than high-density systems, accessibility is its main advantage.

Balancing Density and Accessibility

Some facilities require a balance between storage capacity and product selectivity. The Double Deep Racking System addresses this need by storing pallets two deep, reducing the number of aisles while still allowing reasonable access to stored goods. It is suitable for warehouses with medium-turnover inventory.

| Racking System | Storage Density | Retrieval Method | Suitable Applications | Main Advantage |

|---|---|---|---|---|

| Selective Pallet Racking | Low–Medium | Direct access | General warehousing, retail | High accessibility |

| Drive In Racking System | High | LIFO | Cold storage, bulk goods | Maximizes floor space |

| Double Deep Racking | Medium | LIFO (two pallets deep) | Medium-turnover goods | Balanced density & access |

| Push Back Racking | Medium–High | LIFO | Consumer goods, automotive | Higher density, less forklift travel |

| Pallet Flow Racking System | High | FIFO | Perishables, pharmaceuticals | Supports stock rotation |

| Cantilever Racking Storage System | Low–Medium | Direct access | Timber, pipes, steel | Handles long/bulky items |

| Mezzanine Racking | Medium | Manual/forklift | E-commerce, parts storage | Maximizes vertical space |

Warehouse racking systems differ in design and functionality, catering to a variety of storage needs. Some solutions focus on maximizing space efficiency, others provide easy access to inventory, and certain systems support structured stock rotation. By assessing factors such as product types, storage density, and operational workflows, businesses can choose the most suitable system to improve efficiency, safety, and overall warehouse performance.

Copyright @ 2026 Nanjing Huayide Logistics Technology Co., Ltd. All Rights Reserved.

network supported

network supported

Sitemap / Xml / Blog / Privacy Policy